FOGRod hanging down in wetwell

The Fogrod is extremely simple.. and Simple = Reliable.

This Wastewater Level Sensor works using conductivity. Fresh air is an insulator and water is a conductor. The FOGRod has 10 metal contacts down its length, each one internally connected to a core of 10-core cable. The control panel unit (called the LIT) puts 5v on each wire and looks for current flow to ground. When a metal contact is under water then current flows, and when it is above the water no current flows. So the water acts like a lightswitch and the LIT can determine the level in the wetwell.

The FOGRod hangs by its cable, from a mounting bracket that you install just under the lid. When it needs cleaning just pull it up through the wiper that is an integral part of the bracket.

The FOGRod has no moving parts, no electronics and no sensitive components – so we give it a 10-year warranty in wastewater. It is very tough and designed to be hung in the turbulent part of the wetwell near the inflow.

Always Stops the Pumps – running pumps dry costs lots of money. The FOGRod always stops the pumps because once the wastewater level drops below the bottom of the FOGRod there is no way for current to flow through the fresh air to the receding water level. It’s the laws of physics. Any failure mechanism will stop the pumps.

Cleaning the FOGRod

Always Starts the Pumps – the FOGRod has 10 independent level points, and each one acts as a backup to those below. Suppose you set contact 5 to be your lead start (you wire relay 5 from the LIT into your alternating relay), if contact 5 isn’t working for some reason then the lead pump won’t start. But when the level reaches contact 6 the LIT turns on relays 1-6. So your lead pump starts – just a little higher in the wetwell. And the LIT gives an alarm light and activates a fault relay.

Prevents Short Cycling even with the Worst Rags – the LIT detects multiple contacts going wet together – rags or grease problem – and activates a 3-minute timer to prevent the pumps short-cycling.

Works in Grease – grease is an insulator so doesn’t this stop the FOGRod working? It’s surprising to everyone the first time they see this technology working in wastewater. The reason conductivity rods work in grease is it is almost always “broken up” as it adheres to the rod – especially if you install the FOGRod in its ideal position near the inflow, in the more turbulent part of the wetwell. The LIT gives you an alarm when it sees that the grease is causing measurement problems, and keeps operating as close as possible to the intended start and stop points for a long time after this.

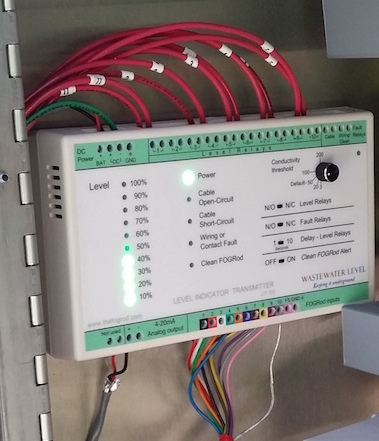

LIT installed in control panel, level relays used for control (top), analog connected to SCADA (bottom left) and FOGRod cable (bottom center)

Control – The LIT has 10 level relays – they are like 10 floats, pick the ones you want to use to replace your floats – no change to your control panel wiring. The LIT has an analog output – this can be used for level control as a replacement for an analog level device like a pressure transducer or ultrasonic.

If you are using the level relays for control, you can connect it to SCADA/telemetry for remote level monitoring.

We offer a FREE trial to any city, town, county or parish. Call us today: 406 545 3023.

Read more about the FOGRod benefits, or see how easy it is to install.