FOGRod – The FOGRod ideally hangs in the turbulent part of the wetwell where the grease is broken up – but not directly under the inflow. Turbulence keeps the FOGRod relatively clean. Screw the mounting bracket into the wetwell wall just below the cover and hang the FOGRod from the S-hook.

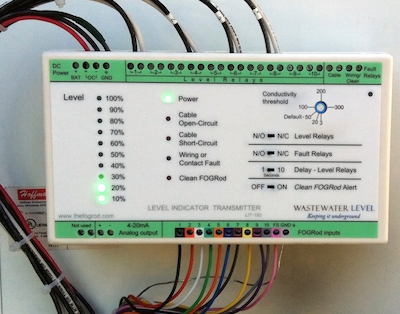

Level Indicator Transmitter – The LIT (Level Indicator Transmitter) clips onto DIN rail in the panel. The FOGRod cable is wired into the color coded terminals.

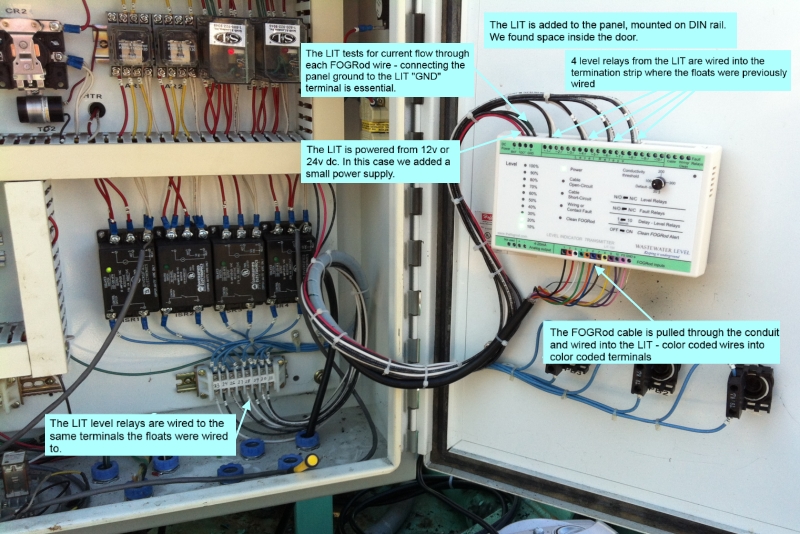

The simplest approach – disconnect the float wires and connect the LIT relays into those same connections. This means that you won’t have to change anything at all in your PLC or control system. So if you currently have four floats wired into lead start, lag start, stop and high level you can simply wire the relevant LIT relay outputs into the same electrical connections in your control panel.

Nothing more to do!

And if you are replacing an ultrasonic, pressure transducer or bubbler, just connect the LIT’s 4-20mA into where the existing level device was wired.

How to Replace Your Floats with the FOGRod

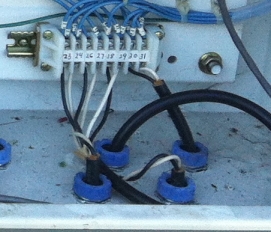

Here is an example of a float replacement in Missouri. Four floats were already wired into a termination strip:

The mounting bracket/cleaning pad was fixed to the wall of the wetwell:

– but because of the geometry of the wetwell we hung the 7.5ft FOGRod from a hook under the metal plate (to the left of the drill in the above photo). The bracket & cleaning pad is for when the FOGRod needs to be cleaned – we just pull it up through the cleaning pad/wiper. The FOGRod cable was pulled through conduit into the control panel.

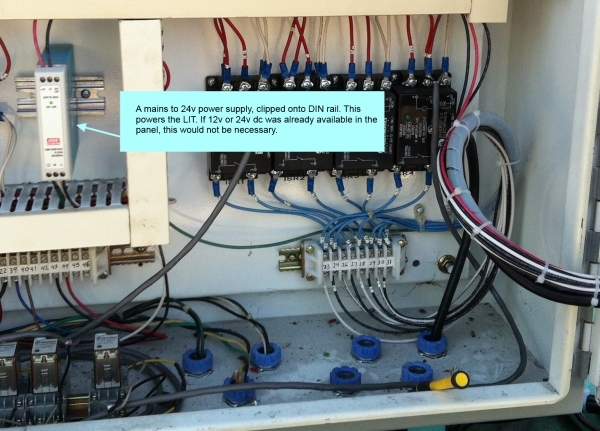

Two holes were drilled in the inner door and DIN rail attached. Then the LIT was clipped onto the DIN rail. The annotation explains the wiring:

Relay 1 – wired into OFF – corresponds to the bottom contact on the FOGRod. Relay 4 – wired into Lead Start – corresponds to contact 4 on the FOGRod. The contacts on the 7.5ft FOGRod are 9 inches apart, so the separation between OFF and Lead Start is 27 inches (3×9).

Moving the lead start up by 9 inches is easily done – we would just move the wires from relay 4 to relay 5. Relay 6 corresponds to contact 6, so Lag Start is currently 18 inches above Lead Start.

The LIT runs off 12v or 24v dc, which was not available in this panel so we added a power supply:

The whole replacement took just over 2 hours.

Installation Photos

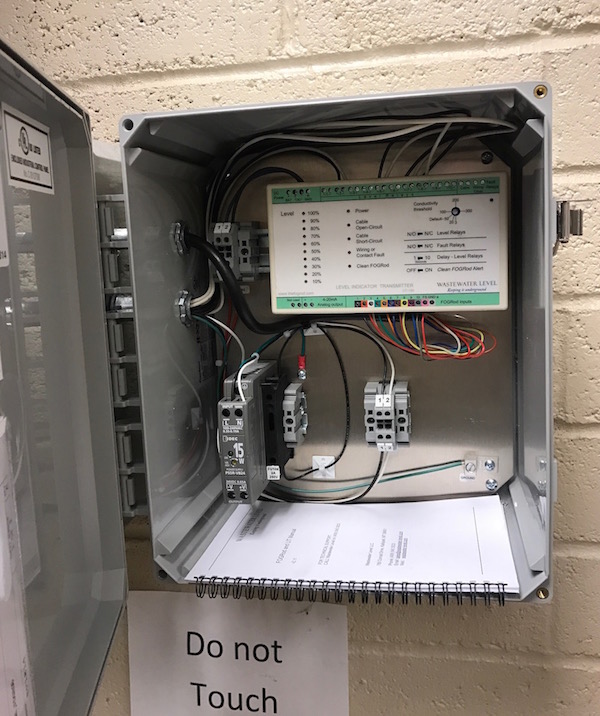

Florida

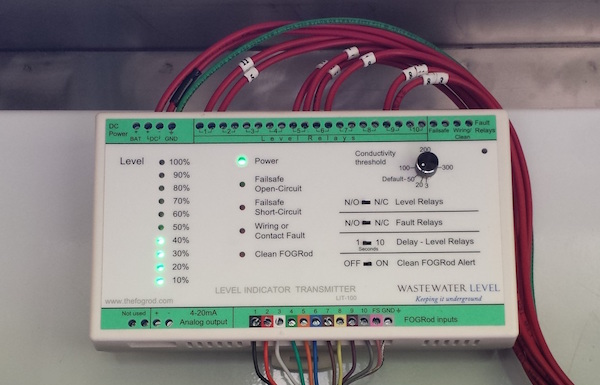

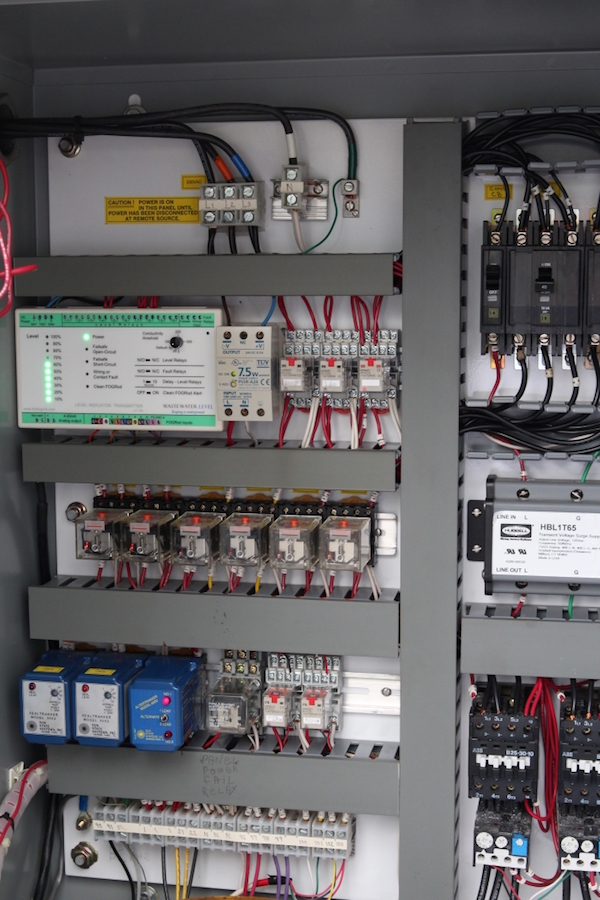

A float replacement in Florida. The Level Indicator Transmitter in the control panel. Contact 1 is used for OFF, contact 5 is Lead Start, contact 6 is Lag Start and contact 9 is Alarm. And note the important ground connection (green wire) – this completes the measuring circuit to detect level:

The FOGRod installation in the lift station:

The mounting bracket and cleaning pad:

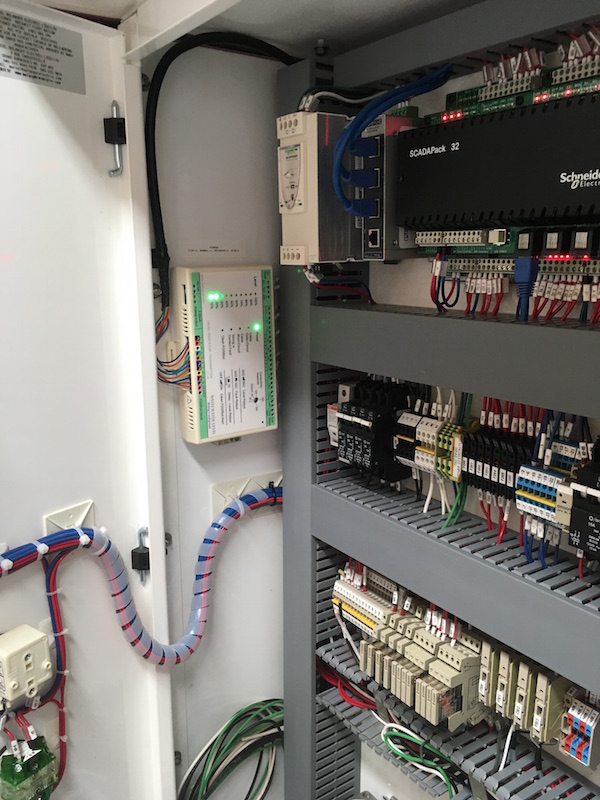

Another site in the same network with the analog output (bottom left) connected to SCADA for remote monitoring of level. Later all of the sites were converted to FOGRods and all were connected up to SCADA for remote level:

Canada – Prince Edward Island

Pennsylvania

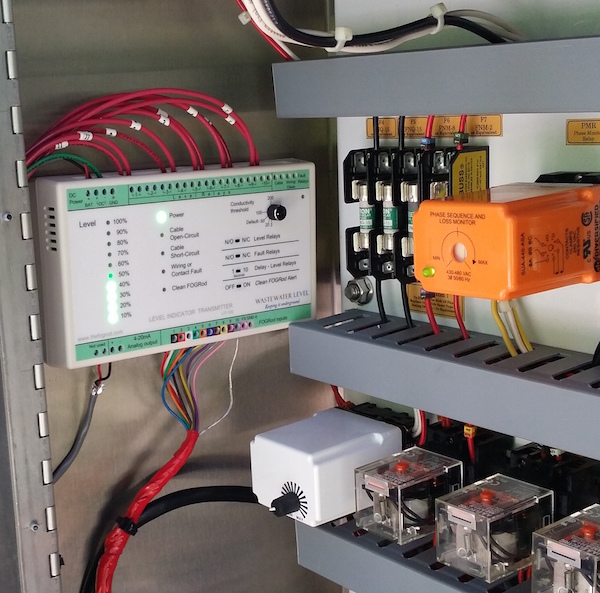

Backup for a transducer in a lift station in Pennsylvania. The control panel with the Level Indicator Transmitter:

The FOGRod in the lift station:

Installing the mounting backet:

Ross on Wye, UK

More UK installation case studies

Tennessee

The FOGRod in the lift station just after installation and some months after being cleaned – but still working fine:

Texas

The FOGRod after 5 weeks:

South Carolina

The LIT in the panel:

The FOGRod in the lift station:

The mounting bracket with cleaning pad just under the lid:

Illinois

The LIT and 24v power supply in the top right and the intrinsically safe barriers at the bottom:

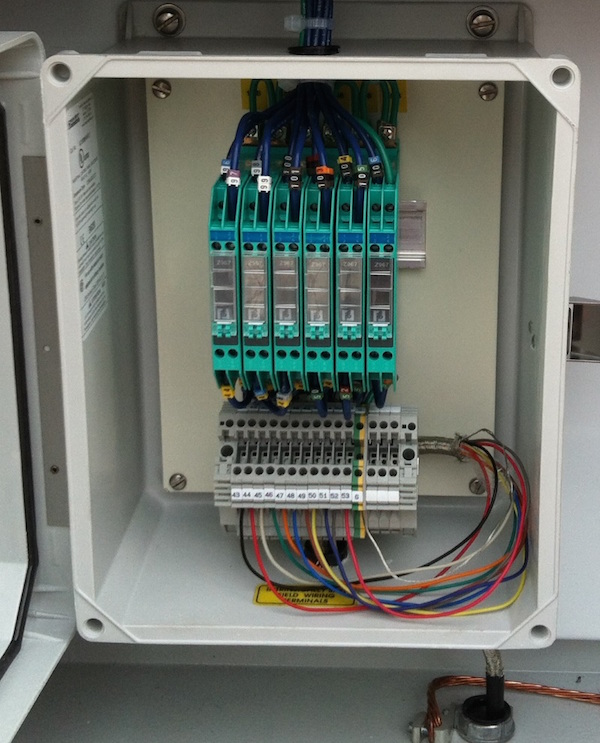

The intrinsically safe barriers to meet Class I Div 1:

The whole panel:

Indiana

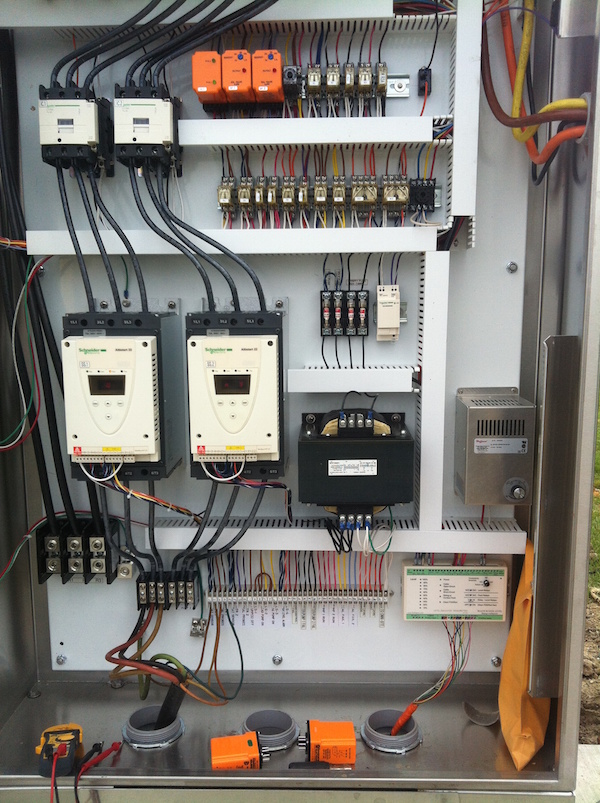

A new control panel with soft-starters. The LIT (Level Indicator Transmitter) is in the bottom right of the panel. You can see the Fogrod cable coming up through the conduit, wired into the bottom of the LIT:

The wetwell – the Fogrod cleaning bracket is in the bottom right corner of the photo, with the Fogrod hanging under the bracket in the bottom of the wetwell. This lift station level sensor can’t easily be seen, but it is hanging in the more turbulent part of the wetwell: